04/30/2015. Remarks by Johan Visschedijk: "No sooner had the development of the MX-334 Rocket Wing begun (1943) than the USAAF established requirements for an advanced Flying Wing fighter-interceptor. The criteria were based on a proposal previously submitted by Jack Northrop in 1942. The secret new Wing was to be an all-magnesium, rocket-powered, prone-pilot fighter-interceptor capable of near sonic speeds.

The prone-pilot concept had once again been chosen to raise the pilot maneuvering "blackout" threshold to 12 g's instead of the 8 g limit of an upright pilot. It also permitted a thinner, lower-drag wing for higher performance. The XP-79B (Project number MX-365) was built with heavy magnesium structure and steel armor plate, designed to enable it to dive on enemy bombers, slicing off tail assemblies to down them (hence its nickname "Flying Ram"). In addition, the XP-79B had provisions for four fixed 50-caliber (0.50 in, 12.7 mm) machine guns in the wing center section, two on each outboard side of the jet engines.

In January 1943, the company was awarded an USAAF contract for the design and construction of three prototypes designated XP-79. Each of the XP-79s was to be powered by a single 2,000 lb (907 kg) thrust rocket motor which was under development by the Aerojet Corporation. Take off was to be boosted by two 1,000 lb (435.5 kg) thrust JATO units. Considering the fighter state-of-the-art of the time, calculated performance was nothing short of spectacular: 518 mph at 40,000 ft (834 kmh at 12,192 m) altitude. Flight endurance, however, was limited to approximately 31 minutes owing to the high fuel consumption rate characteristic of rocket motors.

Unfortunately the above design never reached flight stage. Development of the Aerojet rocket motor was beset by a seemingly endless series of problems. In addition, proven turbojet engines were becoming available. Consequently, the military cancelled the first two aircraft, awarding Northrop a new contract to redesign the third of the three XP-79s for twin axial-flow, turbojet Westinghouse engines. This airplane was designated the XP-79B.

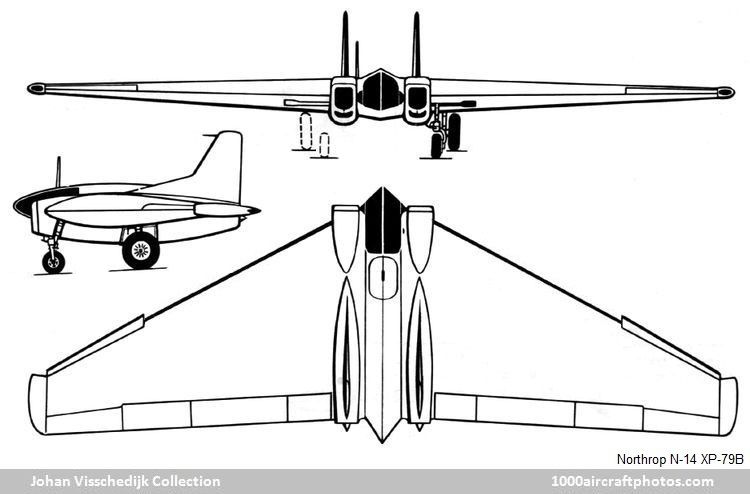

Aerodynamically, the XP-79B was a swept Flying Wing fitted with elevons and bellows-type rudders similar to those used on the XP-56. The prone pilot controlled pitch and roll by means of a crossbar with hand grips at each end. The maneuvering brakes were operated by foot pedals, power-boosted by the air-operated bellows. As in the original XP-79 design, the structure of the "B" was fabricated of Heliarc-welded heavy plate magnesium. Skin thickness varied from 0.75 in (19.05 mm) at the leading edge to 0.125 in (3.18 mm) at the trailing edge, forming a very rigid semimonocoque structure with minimum internal bracing. The outer wing panels were made in two halves, an upper and a lower. These halves were then bolted together. Fuel was carried in the outer panels, the fuel tanks being formed by the wing skins themselves. A four-wheel, electrically retractable landing gear was mounted in the center section.

The pilot's compartment was a sealed cabin designed for a 2.75 psi (0.19 kg/sq.cm) pressure differential; however, the compartment was not pressurized in the prototype. Both upper and lower sealed hatches could be released by the pilot for an emergency bailout. The two 19 in (48.25 cm) diameter 1,400 lb (635 kg) Westinghouse Model B turbojet engines were installed on either side of the pilot's compartment. The windshield was formed of transparent acrylic plastic with a bullet-resistant glass panel located just aft of the windshield and in front of the pilot's face. Armor plate consisting of 0.25 in face-hardened steel was installed just inside of the leading edge of the wing at 45° to the chord plane. The armor extended from the side of the pilot's compartment to the end of the fuel tank on each side. The thick magnesium alloy wing skins also served as armor protection and deflector plates against enemy gunfire.

The prototype XP-79B was trucked to Muroc in June 1945 to be prepared for flight tests. Harry Crosby was appointed test pilot. On September 12, 1945, following several days of preliminary taxi tests, Crosby made the first and only flight. Almost as a forewarning of events to come, one of the attending USAAF fire trucks crossed the marked runway area just as Crosby accelerated the XP-79B on take off. Crosby chopped power just in time to avoid collision, then reaccelerated and took off to about 10,000 ft (3,048 m). He made one sweeping circle over the launch area at extremely high speed, estimated to be over 400 mph (644 kmh). On his second pass over the dry lake at 8,000 ft (2,438 m), Crosby made a climbing turn which became a roll and then a stall. The XP-79B fell off into a nose-down spin from which it never recovered. Observers watched Crosby jump at the last moment. He was struck by a portion of the rotating airframe. The chute never opened.

An accident investigation was unable to determine the cause of the fatal crash because of the total destruction of the airframe in the ensuing magnesium-fed fire. It was speculated, however, that a trim tab failure had occurred, preventing Crosby from making the spin recovery. Following the accident, the program was cancelled and no additional XP-79Bs were produced.