06/30/2015. Remarks by

Kees Kort: "Most likely this is the first of the three prototypes (serial C 3300/16 to 3359/16) of the DFW C.V in its second version. The original design was built with the radiator flush mounted on the upper wing, but because of cooling problems (established in July 1916), the aircraft was modified and was fitted with 'ear' radiators on the fuselage sides."

(

Bernhard Klein Memorial Collection)

06/30/2015. Remarks by

Johan Visschedijk: "One of the most successful two-seaters used by the German AAS was the

DFW C.V, which was eventually produced in large numbers for reconnaissance, artillery cooperation and infantry contact patrol duties. Introduced towards the end of 1916, it continued to equip the AAS units for at least a year, which was a long time for an aircraft to remain in production. Some DFWs continued in service well into 1918, and on the Italian Front they were used right up to the end of hostilities.

There has been much confusion over the exact designation of DFW C.Vs, partly due to their having been license-built by several firms. A great many were built by Automobil und Aviatik A.G., who applied their own Av C.VI designation. The so-called Aviatik C.VI was, in actual fact, a license-built DFW C.V, and should strictly have been designated DFW C.V (Av), in the same way that machines built by the Halberstädter Flugzeug G.m.b.H. were designated DFW C.V (Halb), and those built by the Luft-Verkehrs-Gesellschaft m.b.h. were known as DFW C.V (LVG).

Forerunner of the C.V was the C.IV, powered with the 150 hp Benz Bz III engine, and the basic airframe of this machine was largely retained in its successor. The more powerful 220 hp Benz Bz IV six-cylinder liquid-cooled in-line engine was installed in the C.V, and later the addition of a spinner on the airscrew considerably improved the nose-entry lines. An unusual feature in German aircraft of this period was the cylinder block cowling, which presented a much cleaner appearance. However, these metal cowling panels were often removed in service in the interests of speedier servicing and additional cooling. The familiar funnel-type manifold exhausting over the top of the wing was fitted, although the LVG built machine had a side exit exhaust manifold.

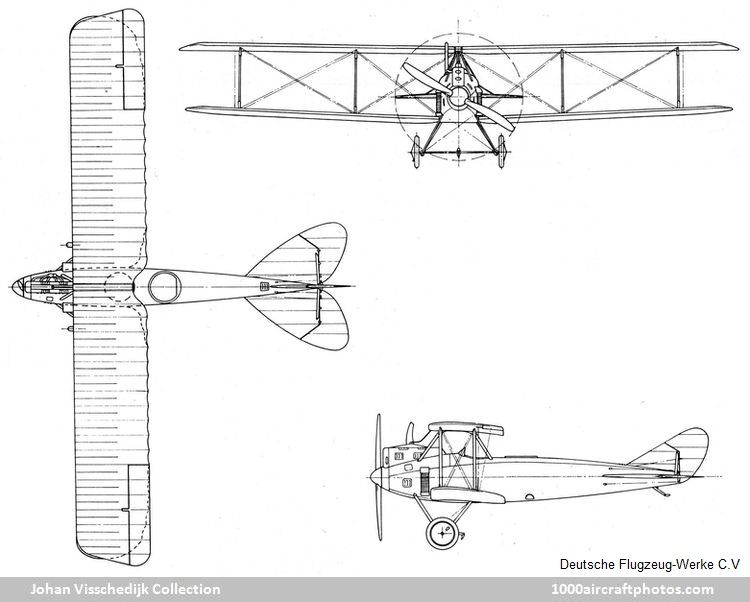

The remainder of the fuselage was a wooden structure, based on plywood formers and four main longerons, terminating in a vertical knife edge, the whole being plywood covered. The style of construction owed much to the Albatros two-seaters, although the decking was rounded off into the slab sides with no sharp edge. Windhoff radiators of "ear" type were mounted on the fuselage sides with the base between the front landing gear strut and leading edge of the lower wing. Towards the end of the production series a single radiator was sited on the leading edge of the center section. The tail plane and balanced elevators were of a distinctive heart-shaped profile and, together with the fin and rudder, were light-gauge steel tube structures with fabric covering.

Of orthodox wooden construction, the wings were based on two box-spars which tapered considerably towards the tips and were wrapped with fabric. The ribs consisted of a plywood web, to which were attached lime or poplar capping strips; false ribs extending as far aft as the rear spar were spaced between. The wire trailing edge member gave the characteristic scalloped effect to the outline.

The upper wings were in two panels, which were bolted to the trestle-type center section cabane, the horizontal member of which incorporated a small reservoir tank of about 0.8 gal (3 l) capacity. The plain tips had a slight outward rake, and the unbalanced ailerons, of steel tube framework, were hinged to an auxiliary spar.

The lower wing followed the same constructional methods, but was of more curved outline, the tips were more elliptical, and a curving cut-out was made at the root to improve the observer's downward vision. The interplane struts were of streamlined steel tube, with small, neat, streamlined pressings on the wing surfaces to shroud the bracing cables.

Streamline-section steel tube was again used for the landing gear V-struts and rubber cord as the shock-absorbing medium. The axle and spreader bars were enclosed in a fairing, and a claw-type brake was mounted in the center of the axle, operated by a lever in the cockpit. The front pair of struts were braced with diagonal cables. A sturdy, steel-shod tail skid was fitted and sprung with elastic cord.

The armament consisted of a fixed Spandau machine gun forward and one manually operated Parabellum machine gun in the rear cockpit."