ROBERT F. PAULEY MEMORIAL COLLECTION

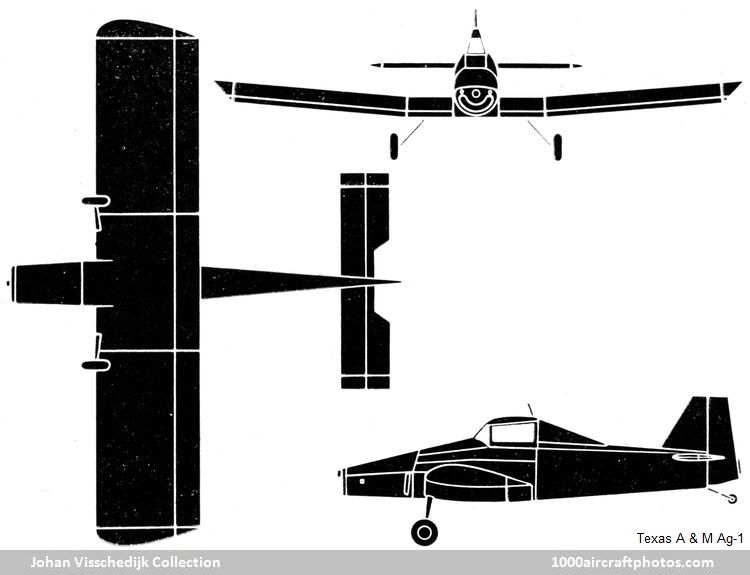

No. 13974. Texas A & M Ag-1 (N222)

06/07/2021. Remarks by

Johan Visschedijk: "The Ag-1, the world's first purpose-built agricultural aircraft, was the result of a program of research on agricultural aviation problems, undertaken at the Personal Aircraft Research Center (PARC) of the Texas Agricultural & Mechanical College (Texas A & M). This program, which was initiated by the National Flying Farmers Association in 1949, in co-operation with the Civil Aeronautics Administration (CAA), the Department of Agriculture, and Texas A & M, included the development of aircraft specifically designed for dusting, spraying, seeding and fertilizing, and improved dispersing equipment. Under a CAA contract, which became effective on December 7, 1949, a prototype was designed built, and this aircraft, the Ag-1, made its first flight on December 1, 1950.

(

Johan Visschedijk Collection)

The Ag-1 was designed by

Fred E. Weick, director of the PARC, to incorporate the characteristics most desired in dusting and spraying aircraft, information on which was obtained from operators partly by personal interview but mostly from a CAA survey which covered the entire country. The aircraft was built by personnel of the PARC, while the project was aided by personnel assigned for various periods by the CAA, the Department of Agriculture, two aircraft manufacturers and the Texas A & M, while many important parts and components, including the engine, airscrew, landing gear, seat, etc., were contributed by their manufacturers. The aircraft was also used in an investigation on dispersing equipment for spray and dust. The partners in the project were listed on both sides of the fuselage of the prototype.

(

Johan Visschedijk Collection)

Ag-1 performance included low speed with high-lift, having a powerful fullspan flap. Of particular importance in basic design, the pilot was given unusual visibility forward and downward, while in turns close to the ground. In addition, great effort was made to provide adequate protection for the pilot-effort which subsequently proved to be thoroughly justified. Weick designed also a shoulder harness-seat belt combination for the AG-1. The general configuration, an angular fuselage, low wing, steep slope of engine cowling and raised cockpit, was later adopted worldwide for many ag-plane designs.

In the summer of 1951, the Ag-1 successfully completed a seven weeks service test-demonstration tour of the Southwest and Middlewest of the USA. In the 4,180 mls (6,727 km) portion of the tour in the Southwest alone, the aircraft performed in 24 centers of agriculture aviation activity, and was flown by 147 different pilots, who were enthusiastic, particularly about the handling characteristics. During a demonstration flight before the American Cotton Congress in August 1953, the Ag-1 collided with a power line near Lubbock, Texas and crashed. The aircraft cart-wheeled and ended up inverted, almost totally destroyed. Due to the protective features of the cockpit, the pilot, John Paul Jones, a CAA safety agent, walked away without injuries.

Type: Single-seat Experimental Agricultural monoplane.

Wings: Low-wing cantilever monoplane. Modified NACA 64021 wing section. All-metal construction. Full-span slotted flaps and slot-lip ailerons. Detachable wing-tips.

Fuselage: Rectangular metal structure with domed after deck.

Tail unit: Cantilever monoplane type. All-metal structure. Detachable tips.

Landing gear: Tail-wheel type. Cessna-type spring steel struts for main wheels and spring for tail-wheel. Goodyear main wheels, low-pressure tires and brakes. Scott steerable and full-swiveling tailwheel. Main landing gear legs were sharpened so as to cut any wires or cables encountered in flight.

Poer plant: One 225 hp Continental E-225 six-cylinder horizontally-opposed air-cooled engine driving a McCauley two-blade one-piece aluminum-alloy airscrew. Fuel tank in fuselage behind engine bulkhead.

Accommodation: Open cockpit over trailing edge of wing. Decking forward of cockpit sloped 15°. Headrest formed a turnover structure and guide tubes from windscreen to headrest and cable from headrest to top of fin provided for protection against cables or wires contacted in flight.

Equipment: Hopper for dust, seed or fertilizer in fuselage in front of cockpit with, initially, an adjustable sliding gate and distributor beneath fuselage. Two synthetic rubber-lined tanks for spray liquid in center-section, one on each side of fuselage. Engine-driven pump delivers liquid through manifolds to outlet nozzles. The spray boom was located within wing contour from tip to tip. There was room in outer wings for installation of additional experimental dust hoppers.