12/15/2021. Remarks by

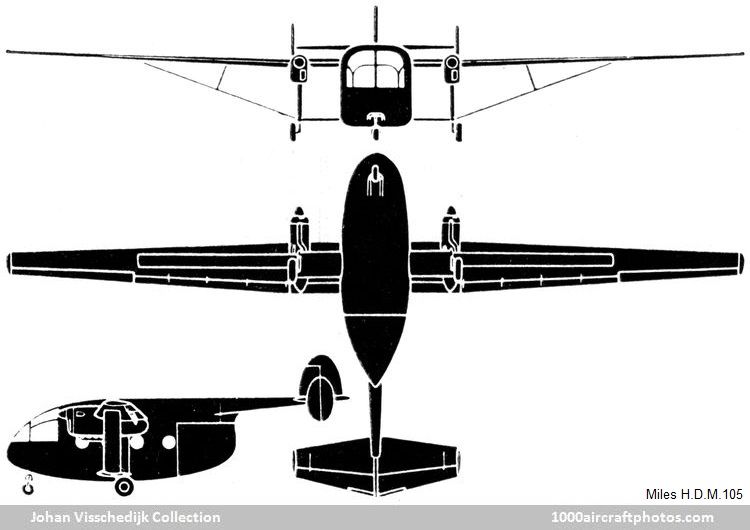

Johan Visschedijk: "The H.D.M.105 marked a significant change in the Miles policy towards aspect ratio. Previously nearly all Miles designs had been based on the use of low aspect ratio wings. After the war the French firm of Hurel-Dubois, had pioneered a series of aircraft having wings of exceptionally high aspect ratio such as are normally found only on high-efficiency sailplanes. This was based on the belief that in aircraft designed for low cruising speeds, the reduction in induced drag would more than offset the increase in structure weight of a wing with an aspect ratio of the order of 20.

Early in 1955 George Miles recognized the possibilities of this argument and he decided that some full-scale comparative tests would be valuable to support the data obtained with the various Hurel-Dubois aircraft

already built.

To obtain comparative data as quickly and cheaply as possible, it was decided to take a

standard Aerovan Mk.4 (registered G-AJOF c/n 6403) and to fit it, with as few modifications as possible, with a wing of Hurel-Dubois design. The aerodynamic design of the wing and also the tentative scheme drawings for the wing structure were done by the Societe de Construction des Avions Hurel-Dubois at Villacoublay, France. The remainder of the design, drawing and construction was done by F.G. Miles Ltd. at Shoreham, West Sussex, the costs being shared by the two firms.

The wing, which was of all-metal construction, had a span of over 75 ft (nearly 23 m) and a root chord of only 55 in (1.4 m), giving an aspect ratio of 20.5:1. The wing section was an NACA laminar-flow section, 63

4-420 to the inboard end of the ailerons, tapering to NACA 63

1-412 at the tip. It was supported by lift-section diagonal struts of high aspect ratio. Double slotted flaps were fitted and operated, as in the case of the standard Aerovan, by Miles electric actuators. The Frise-type differential ailerons were interconnected with hinged spoilers fitted to the upper surface of the wing.

Power plant consisted of two 155 hp Blackburn Cirrus Major III four-cylinder air-cooled inverted in-line engines, driving Fairey fixed-pitch metal propellers. The landing gear was fitted to a small stub wing, the vertical struts functioning as fuel tanks. The remainder of the aircraft was standard Aerovan with wooden nacelle and metal tail boom.

The standard Aerovan Mk.4 emerged from the Miles works rebuilt with Aerovan Mk.VI tail surfaces and the new wing, virtually a scaled down version of that used on the Hurel-Dubois HD.32.

Miles H.D.M.105 (G-35-3) (

Johan Visschedijk Collection)

Given with the new c/n 105/1009, redesignated H.D.M.105, and carrying the Class B marking G-35-3, it was first flown by Chief Test Pilot Ian A. Forbes on March 31, 1957.

Miles H.D.M.105 (G-AHDM) (

Dan Shumaker Collection)

It was appropriately registered as G-AHDM on April 18, 1957.

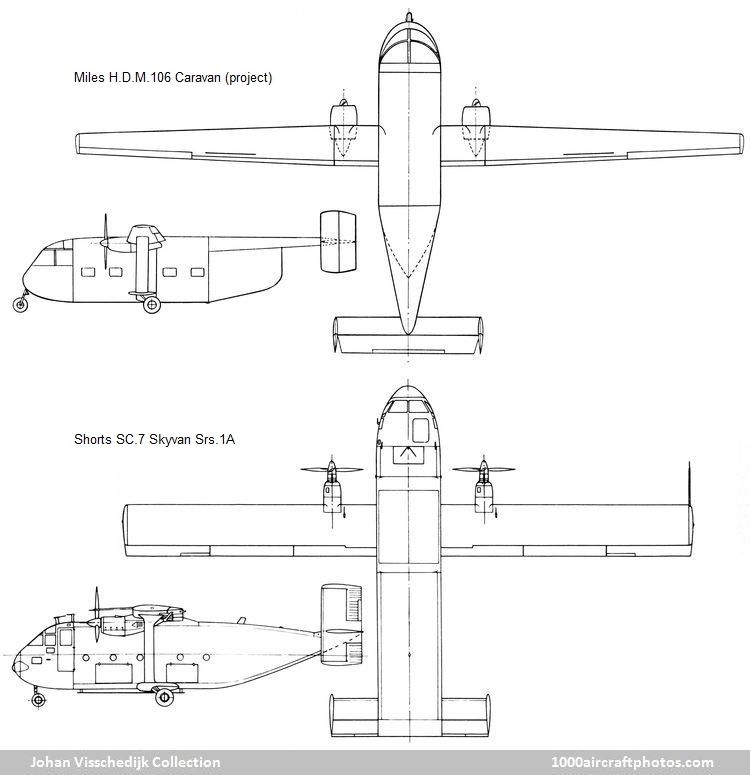

Following the successful trials of the H.D.M.105, a company called H.D. et M. (Aviation) Ltd, was formed jointly by Miles and Hurel-Dubois to exploit derivates of the H.D.M.105. G-AHDM was reregistered to the new company on December 10, 1957. However, six months later it was damaged beyond repair in a landing accident at Shoreham on June 28, 1958.