02/28/2014. Remarks by

Johan Visschedijk: "In 1972, Grumman Corporation had purchased 80% of the issued stock of American Aviation and changed the name of the company to Grumman American Aviation Corporation (GAAC). The 2,000th aircraft was rolled out in October, 1974 from the Cleveland, Ohio plant, but Grumman American moved all production of its light aircraft range to Savannah, Georgia in 1976. On September 1, 1978, the Grumman Corporation sold its holding in GAAC to American Jet Industries and GAAC was renamed Gulfstream American Corporation.

(N777GA) (

Johan Visschedijk Collection)

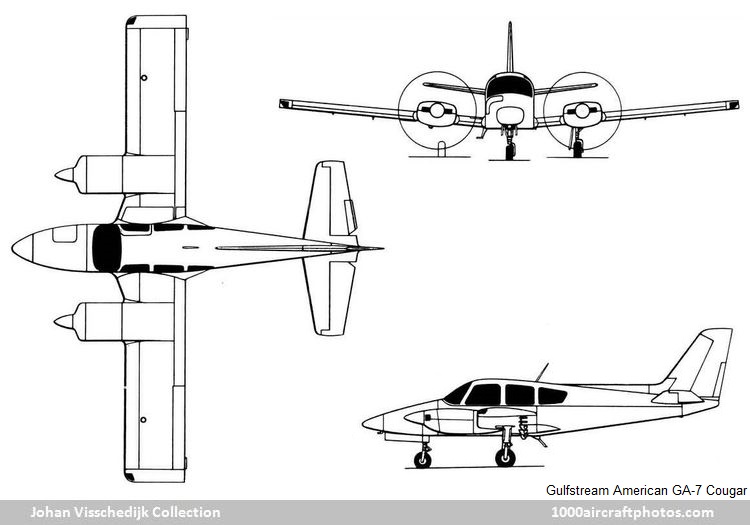

In 1974, the company developed a light twin which was viewed as a logical development of the full product range. The prototype GA-7 Cougar N777GA first flew on December 20, 1974. It had a similar wing to that of the AA-5 and featured a sliding canopy and twin 160 hp Lycoming O-320 engines. Accommodation was for four people and the aircraft had a retractable tricycle landing gear.

During testing of the prototype it became clear that the sliding canopy was unsatisfactory for this type of aircraft and the production prototype (N877X c/n 0001), which first flew January 14, 1977, adopted an integral cabin with a starboard side door, a third window on either side and construction based on the bonded methods of the single-engined Grummans. The Cougar gained its type certificate (A17SO) on September 22, 1977, delivery of production aircraft began in February 1978, and only 115 examples were built.

SOCATA TB 320 (F-WWRS) (

Ron Smith Collection)

In 1995, the GA-7 Type Certificate was acquired by Aérospatiale's light aircraft division SOCATA of France, with the intention of developing and producing the type as the TB 320 Tangara, later redesignated TB 360. A modified GA-7 (registered F-WWRS) first flew in mid-1996 and an other, even more modified example, flew in February 1997, however, the type was not taken into production."

The following data relate to the GA-7.

Type: Four-seat lightweight cabin monoplane.

Wings: Cantilever low-wing monoplane. Dihedral 5°. Wing section

NACA 63A-415 (modified). All-metal two-spar structure of light alloy with wing skins attached to ribs and spars by metal to metal bonding techniques. Electrically-operated single-slotted Fowler-type trailing edge flaps of light alloy. Plain ailerons of light alloy construction. Aileron trim system. Conical camber wing tips.

Fuselage: Cabin area of aluminum honeycomb construction; semi-monocoque rear fuselage structure of light alloy, using metal to metal bonding construction.

Tail unit: Conventional cantilever structure of light alloy, with swept vertical surfaces. Trim tabs in rudder and each elevator.

Landing gear: Hydraulically-retractable tricycle type with single wheel on each unit. Steerable nose wheel retracts forward, main units outward into undersurface of wing. Oleo-pneumatic shock-absorbers. Free-fall emergency extension system. Main wheels have 17x6.00-6 six-ply tires, nose wheel has 15x6.00-6 four-ply tire. Toe-operated hydraulic brakes. Parking brake.

Power plant: Two 160 hp Lycoming O-320-D1D flat-four engines, each driving a 6 ft 1 in (1.85 m) Hartzell HC-F2YL-2UFIFC7663D-3 two-blade constant-speed fully-feathering metal propeller with spinner. Integral fuel tank in each wing, with a combined capacity of 118 gal (447 l). Refueling point on upper surface of each wing. Oil capacity 4 gal (15 l).

Accommodation: Four seats, in two side-by-side pairs, in enclosed cabin. Dual controls optional. Over-wing door on starboard side of fuselage. Baggage space aft of rear seats with external access door on starboard side. Door on starboard side of nose section to give access to battery and electronics, as well as an additional 12 cu.ft (0.34 cu.m) of baggage space. Provision for lightweight radar antenna in nose cone. Heating, ventilation, and windscreen defrosters standard.

Systems: Hydraulic system for landing gear actuation and operation of brakes. Electrical system includes 14V 60A engine-driven alternators, 14V voltage regulators and a 12V battery.

Avionics and equipment: Narco Com 120/Nav 121 and associated equipment optional. A wide range of optional avionics and autopilots by Collins, Edo-Aire Mitchell, King and Narco. Standard equipment includes lap belts and shoulder harnesses, front seats with inertia reel; front seat armrests; carpeted floor; instrument panel glare shield; hat shelf; map compartment and storage pockets; pilot's storm window; fold-down rear seat; soundproofing; controllable instrument panel lighting; cabin dome lights; indirect instrument panel lighting; navigation lights with detectors; audible stall warning device; sensitive altimeter; dual manifold pressure gauge; alternate static source; cabin step; tie down rings; elevator and aileron gust locks; and polyurethane external paint scheme.

Optional equipment for GA-7 includes items standard on the de luxe version, plus encoding altimeter, sensitive altimeter, hour recorder, true airspeed indicator, turn and bank indicator, external power socket, nose baggage compartment, control wheel microphone, internal corrosion proofing, stainless steel control cables, exhaust gas temperature gauge, map light, lighting package including rear reading, baggage compartment, exterior step and wing lights, propeller unfeathering accumulator, and rear-seat ventilation system.

The

de luxe version of the GA-7 has the following additional avionics and equipment as standard: Narco Com 120/Nav 121 and associated equipment (M-700B microphone, Telex headset, speaker, jacks, antennae, wiring, and radio cooling kit); electric dock; direction and horizon gyros with pressure system; turn coordinator; vertical speed indicator; outside air temperature gauge; dual controls; glove box; tinted windscreen and windows; landing light; strobe lights; heated pitot; quick oil drain valves; and towbar.